Radiofrequency Identification (RFID) technology is used by many industries as a means of warehouse management, inventory applications, and tracking purposes. RFID is great for companies because you can scan, identify, and locate items without having to be in direct line-of-sight of the item. RFID technology has streamlined processes for the shipping and packaging industries.

Ultra-high frequency (UHF or RAIN) RFID is a passive, wireless, and battery-free technology that allows users to identify and locate up to one thousand items per second within 32ft, without being in direct line-of-site. This is helpful for industries that regularly scan pallets of items at one time. The use of RAIN RFID technology saves companies countless hours of time and money.

Selecting the Right RFID Tag

There are many different options of shapes and sizes when selecting the RFID tag that will work best for your business needs. The first decision you need to make is whether you need an active or passive RFID tag and understand the capabilities of each type.

- Active tags – Due to their design and battery, active tags are typically larger than passive tags. A benefit of active tags is the capability for a longer read range which is generally more expensive than passive tags.

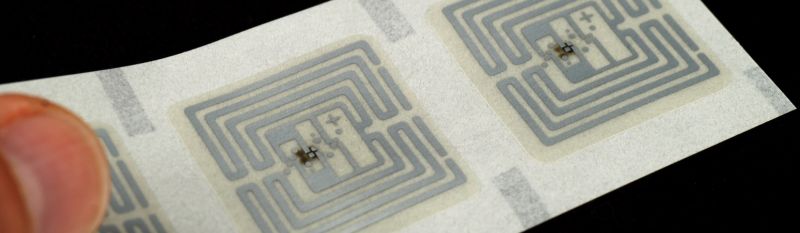

- Passive tags – More cost-effective, passive tags are typically used in the form of labels that can be attached to an item or a box during transit. Retail stores usually use passive tags because it is economical to attach them to individual items that can later be discarded.

It is important to think about the item you are tracking and the value of the item itself when considering what type of RFID tag would work best for your business.

Frequency

Consider what materials are being tagged, the data rate, and the requirements for the read range. RAIN RFID tags can be used in many different applications and use a range of frequencies known as the UHF (Ultra-High Frequency) radio band.

Make sure to check for your region’s compliance standards regarding RFID deployment.

Read Range

Businesses require different read range and performance requirements, and determining the RFID technology needs for your business will help you choose the correct RFID tag. Larger facilities, such as manufacturing and warehouse facilities, will have a different read range requirement than smaller businesses such as retail stores.

Consider the Materials to be Tagged

If you are tagging items that contain water or items such as animals, a Low-frequency (LF) or High-frequency (HF) tag would work best because they can be read through liquids.

Items that contain metal typically use a UHF, or RAIN, RFID tag because the metal can interfere with the frequency.

Tag Location

RFID tags are designed to be attached to a wide range of different surfaces and can be applied in label form, applied directly on the item’s surface, or attached as a hangtag. Items such as wood, plastic, and cardboard typically use RFID tags that are embedded on the non-metal surface. Make sure your RFID tag placement does not obstruct important information on the container such as important instructions, disclaimers, etc.

RFID tags can be attached to items using a strong adhesive, being sewn into the material, or with the use of a screw for items such as wood. You want to make sure the tags are secure and will not come off or become unattached.

Environmental Factors

The environment can affect the RFID tag if weather conditions reach high or extremely low temperatures, so choosing a durable RFID tag that can withstand the environmental factors it will encounter is vital for the tag’s overall performance.

Tamarack® Products offers clients over 50 years of experience designing customized web-finishing equipment, such as the MVW Inline RFID inlay insertion system. The MVW Inline is modular, scalable, and servo-driven for easy installation and operator-friendly controls.

Tamarack Products provides solutions using RFID technology with our fully customizable and scalable MVW Inline RFID inlay insertion system that can be completely integrated into your existing flexo press. Contact us to learn about our integrated web-finishing solutions and how to select the right RFID tag for your unique business needs.