Description

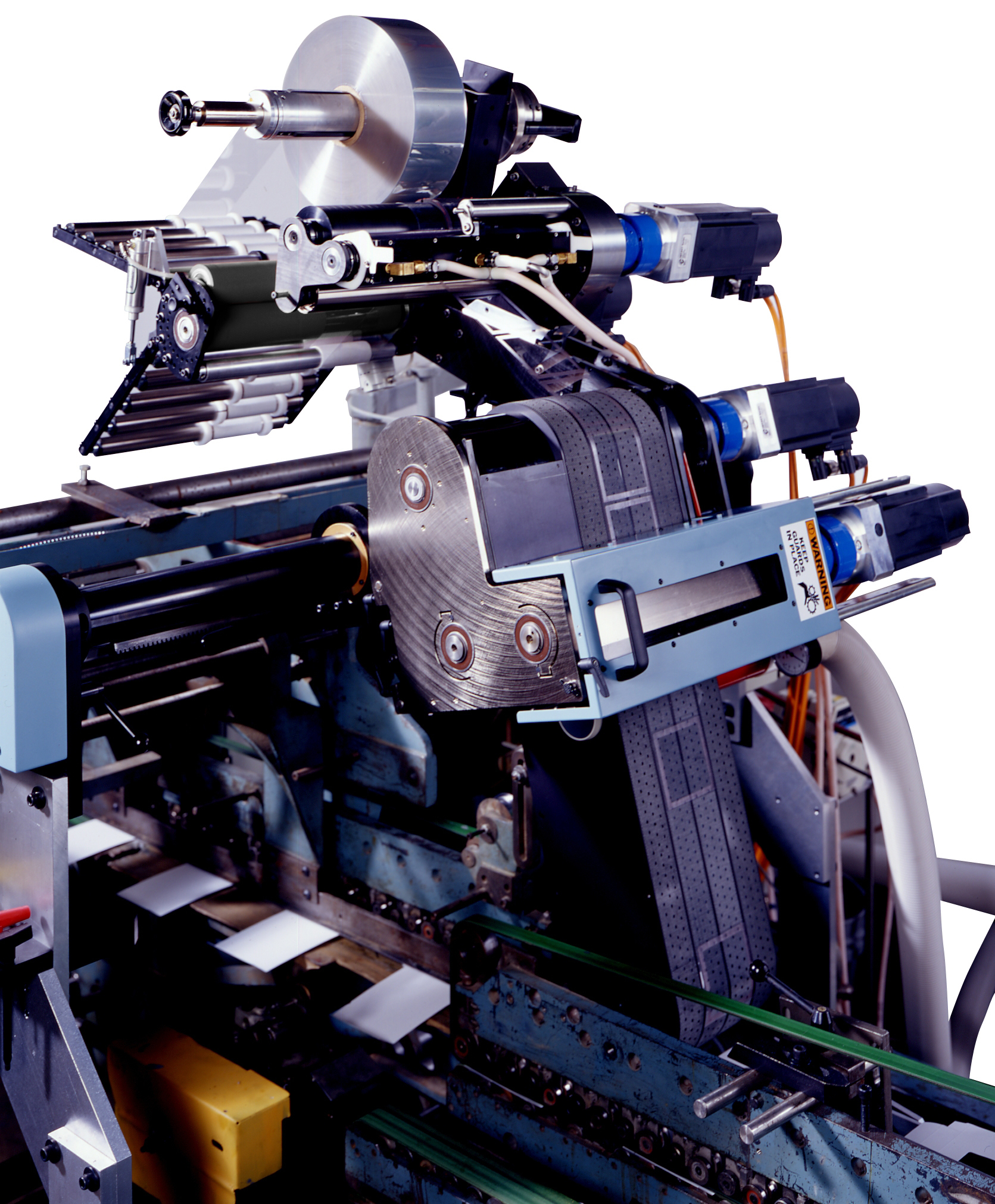

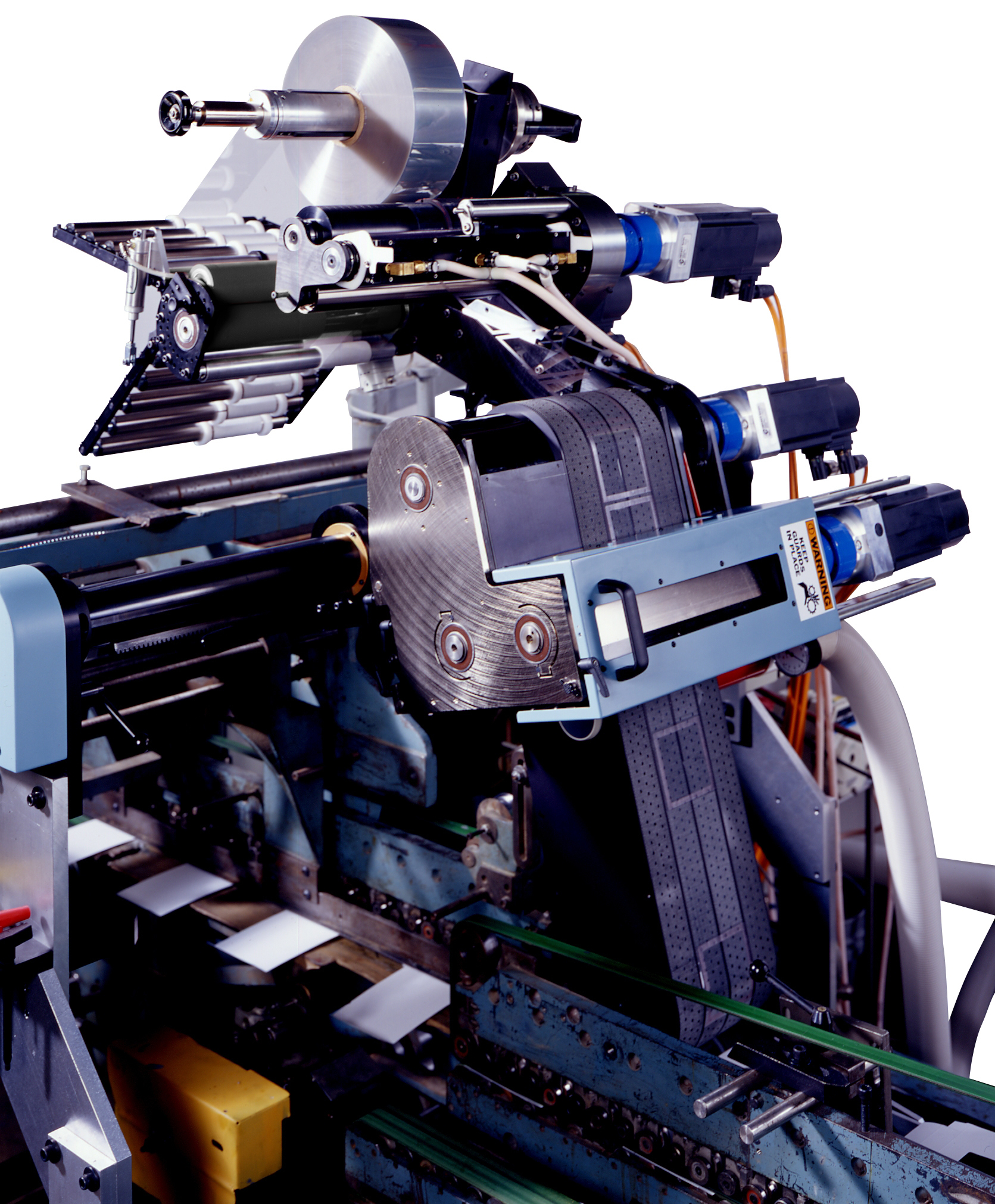

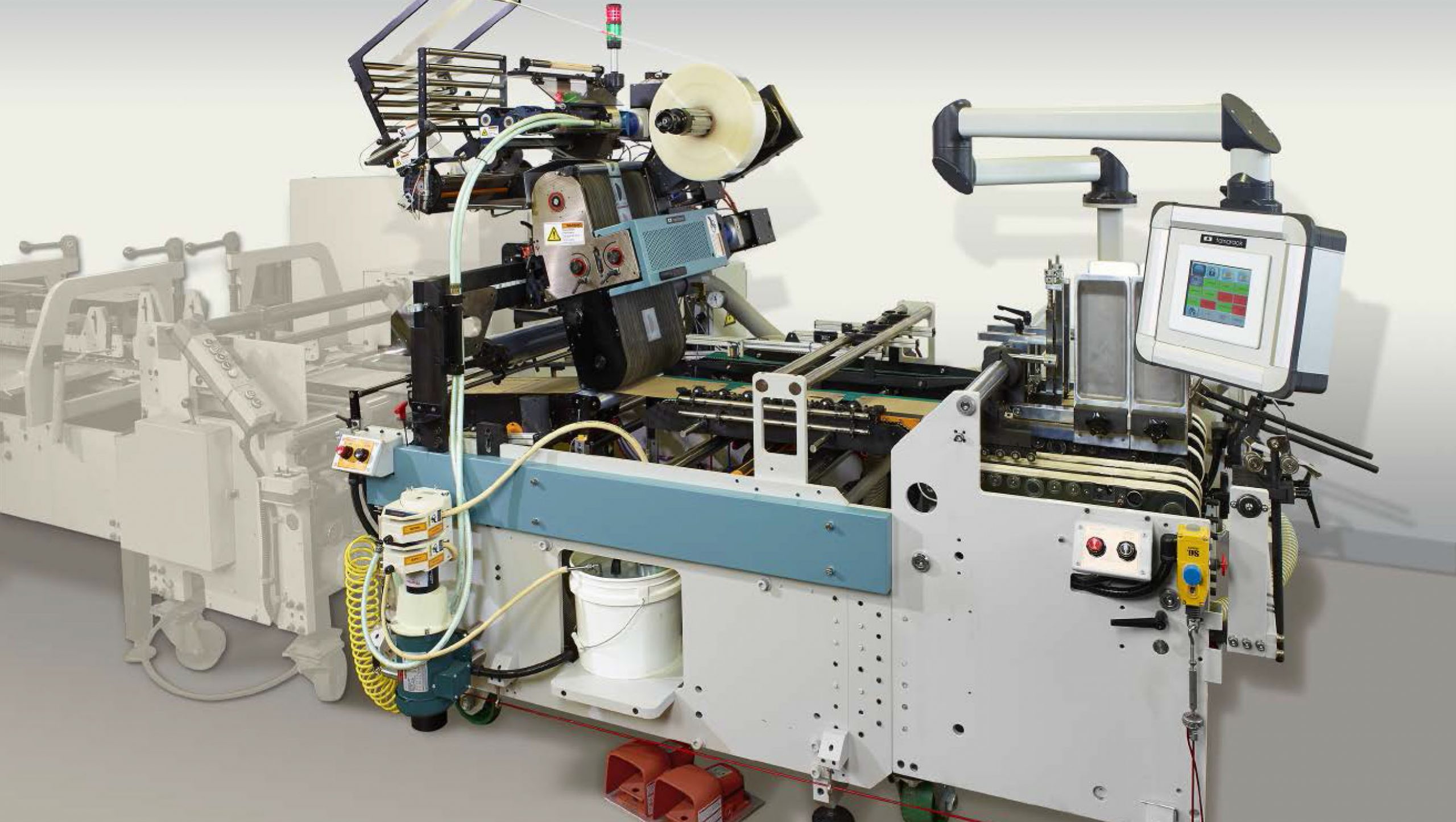

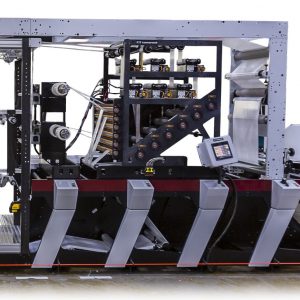

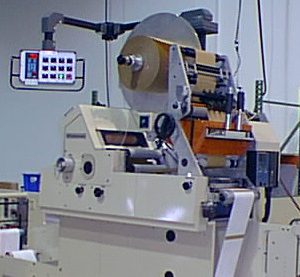

The Vista® in-line window patching equipment installs on new or existing folder-gluers to combine carton windowing and gluing in a single pass. With this innovative approach, you save floor space, labor costs, staging and handling of carton blanks. Additionally, film material costs can typically be reduced by 10-20% per job due to a reduction in film size thanks to excellent adhesive and window patch placement accuracy.

Tamarack Products is a leading window patching machine manufacturer offering the Vista Window Patcher, carton windowing equipment that installs on your press or specialized web finishing lines. Install the Vista on your folder or gluer to achieve high productivity with a new approach to carton windowing.

In-Line Window Patching Equipment

This innovative carton windowing equipment provides versatility to apply tapes, coupons, holographic foil and more with servo technology. Tamarack’s Vista streamlines your operations with rigid window die cutting, susceptor patch application, and inline patching of envelope closures, hole reinforced laminates, and more. The Vista meters, cuts off and applies most roll fed materials.

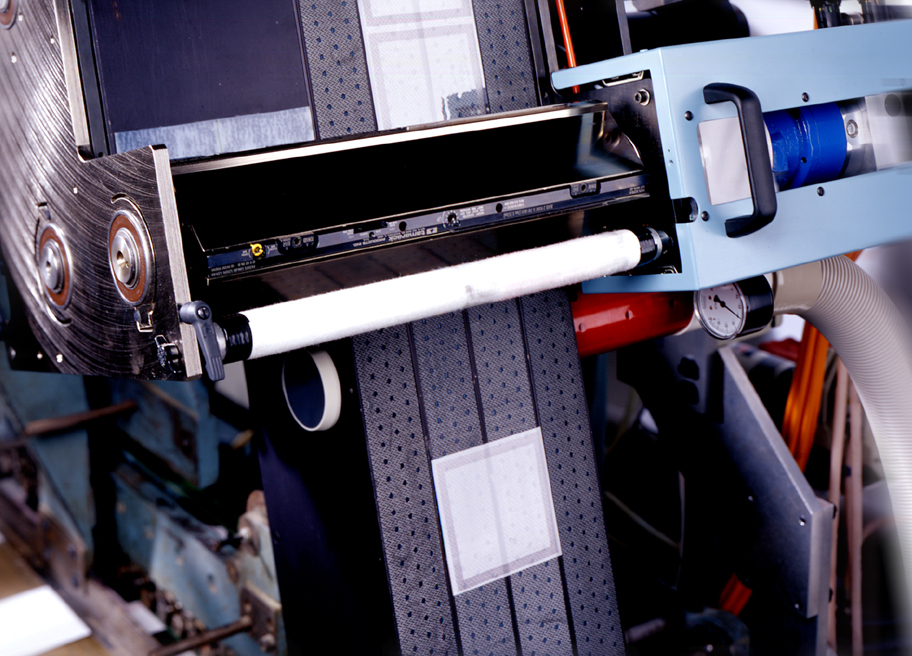

The Vista provides high quality with excellent window registration and vacuum belts to deliver the window to the carton with optimized speed and accurate placement. The self-contained drive system and sleek design easily integrate into your new or existing folder-gluer. The glue applicator prints glue patterns on demand and maintains glue level.

Efficient Carton Windowing Equipment

The Vista in-line window patching machine supports high-volume with speeds up to 500 FPM, typically 20,000 to 30,000 cartons per hour. A high speed option is available which can increase speed to 50,000 per hour on some jobs. Enjoy quick setup time in 30 minutes or less and quick cleanup in 20 minutes or less with a lightweight, removable plate and fountain cylinders.

Modular and Customized In-Line Window Patching

The Vista is designed and engineered with modular construction to allow window patching between belt carriers. Through the use of coated rollers and vacuum belts with exposed cotton fibers, the Vista virtually eliminates window scratching. With servo controlled technology, the Vista provides high-quality in-line window patching with a variety of window materials for your customized packaging.

Tamarack offers customized solutions for applications such as die cut polyethylene on tissue boxes, RFID tags or security devices.

Tamarack Products designs, engineers, and manufactures high-quality web finishing machinery and equipment, customized to meet unique customer requirements. We offer more than 50 years of experience in providing exceptional service and responsiveness to our customer needs. Contact us to learn more about increasing your efficiency and productivity with the Vista in-line window patching equipment.

Tammi Davis –

“Tamarack has been everything we look for when buying equipment and have gone above and beyond to make sure we are successful.”

-Tammi Davis, Post Press Specialties