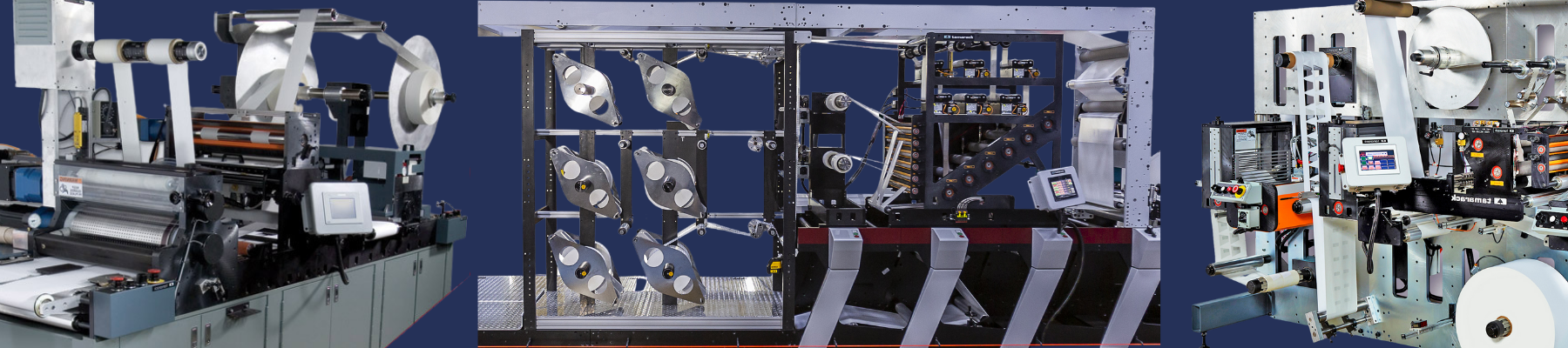

Customized Web Finishing Equipment

Tamarack Products designs, engineers, and manufactures customized web finishing equipment used in the packaging, label, and forms industries with modular, customized finishing solutions.

We offer more than 50 years of experience in producing finishing equipment for patching, gluing, and die cutting rolls of material that are placed on other substrates to yield products with value added elements. Tamarack’s equipment provides efficient and cost-effective solutions to the following industries:

Packaging – adding plastic film to folding cartons, tissue carton windowing, printed film, rigid windowing, courier envelopes, susceptor patches for microwave packaging and more.

RFID – we provide customized solutions for producing RFID labels, tags, tickets, or cards used for various industries and applications.

Forms and Direct Mail – our modular equipment provides solutions to the forms and direct mail industries to create custom integral labels, cards, forms or magnets, windshield stickers, scratch off patches and more.

Our team of experienced engineers, machinists, and programmers provide customized equipment solutions to meet your unique application requirements.

Modular, Scalable, Customized Web Finishing Equipment

Tamarack differs from other finishing equipment manufacturers in our responsiveness to our customers’ needs and ability to create modular and customized equipment solutions. When you bring your application requirements to Tamarack, we listen carefully to understand your product and feature requirements and work with you to develop a production solution. Our creative team provides innovative production approaches with customized equipment solutions, servo programming technology, motion control expertise, and the ability to integrate equipment into your existing production line. Tamarack offers the expertise to route and control webs, provide gluing, die cutting, patching, and affixing to various substrates including cartons, paper, labels, bags, and film.

We realize that every application is unique, and some may require only die cutting or only gluing, while other applications may require changes and additions in the future. With our modular design, we provide the scalability to help our clients expand their application without the need to purchase new equipment.

Custom Web Finishing Applications

Tamarack customizes your web finishing equipment to meet your application demands with projects such as these:

- Affixing windows and liners to cartons inline on a folder-gluer for food packaging.

- Affixing clean release and laminate materials to digitally printed forms to produce integral ID cards on demand.

- Affixing microwave susceptor patches inline on press to produce microwave popcorn bags.

- Inserting RFID inlays to produce shipping labels, apparel tickets, transit tickets and airline bag tags.

- Die cutting, scoring, and affixing window film to produce rigid window cartons inline on a folder-gluer.

Custom Gluing, Patching, Die Cutting Systems

Tamarack’s custom gluing, patching and die cutting systems include specialized equipment such as for integration of hot melt adhesive, cold gluing, integration of RFID inlays, patching, affixing or peel-off materials, to name just a few. We excel with engineering custom equipment to provide the unique features your application calls for, with efficient and cost-effective production solutions.

Tamarack Products is an industry leader in manufacturing inline and offline web finishing equipment with custom engineering. We offer a highly skilled team that is committed to your total satisfaction and success with exceptional responsiveness to our customer needs. Contact us to optimize your web finishing application with customized equipment and production solutions.