RFID (Radio Frequency Identification) technology has become a cornerstone of modern inventory tracking and various business practices. RFID tags offer a contactless tracking method, enhancing the convenience and speed of transactions for users worldwide. This blog explores the workings of RFID tags, tickets, and labels, the chip inlay process, and introduces Tamarack’s MVW Inline RFID Inlay Insertion Equipment as a pivotal solution in the production of RFID-enabled financial tools.

Understanding RFID Tags, Tickets, and Labels

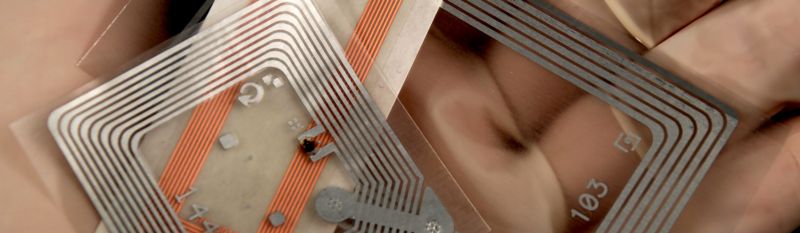

RFID tags utilize radio frequency technology to communicate with terminals without physical contact. Embedded within these tags are an RFID chip and antenna; together, they form an inlay that enables the card to transmit information to a nearby reader through electromagnetic fields. This contactless feature allows for faster transactions and record-keeping than traditional methods.

How RFID Tags Work

The magic of RFID tags lies in their inlay’s ability to harness electromagnetic energy from the RFID reader. When an RFID tag is brought into the proximity of a reader, the reader emits a specific radio frequency that powers the tag’s chip. This activation allows the chip to transmit a code, or token, representing the card’s information to the reader, which then processes the transaction. Importantly, because the transmitted token is unique to each transaction, RFID credit cards offer a secure method to prevent fraud and cloning.

The RFID Chip Inlay Process

The creation of RFID tags or labels involves a sophisticated manufacturing process known as the chip inlay process. This process includes the integration of the RFID chip and its antenna into the label, ensuring seamless functionality and durability. The steps typically involve:

- Antenna Embedding: An antenna is laid out or printed onto a substrate material, forming the basis for communication with card readers.

- Chip Attachment: An RFID chip is then attached to this antenna. The chip stores information and performs the tag’s communication functions.

Tamarack’s Contribution: The MVW Inline RFID Inlay Insertion Equipment

Recognizing the critical role of RFID technology in many sectors, Tamarack Products introduces the MVW Inline RFID Inlay Insertion Equipment. This advanced machinery is designed to streamline the production of RFID labels, tickets, and tags, by applying the inlay, which is the antenna and the chip. The MVW Inline RFID Inlay Insertion Equipment integrates seamlessly into new or existing Flexo presses. Here’s how the MVW Inline stands out:

- Servo-Driven Technology: The MVW Inline’s servo-driven system simplifies integration with your press, ensuring smooth and efficient operation.

- Versatile Inlay Insertion: Capable of inserting both lower cost, dry inlays and wet inlays, the MVW Inline offers flexibility to meet diverse manufacturing needs.

- User-Friendly Operation: With operator-friendly controls, fast setup, and a simple web path, the MVW Inline allows for the productive completion of short-run jobs and trials, making it an invaluable tool for manufacturers looking to capitalize on the RFID market.

The MVW Inline’s introduction marks a significant advancement in RFID inlay application, offering a cost-effective, efficient solution for embedding sophisticated RFID technology into tags, cards, and labels. With its precision and versatility, the MVW Inline is poised to support the growing demand for RFID-enabled solutions, reinforcing security and enhancing user convenience.

The chip inlay process is central to the production of advanced RFID tags, requiring precision and expertise. Tamarack Products’ MVW Inline RFID Inlay Insertion Equipment emerges as a key player in this field, providing an innovative solution for the efficient production of RFID-enabled labels, tickets, and tags.

As the world moves towards more advanced RFIC technologies, Tamarack stands ready to support this transition with cutting-edge equipment designed to meet the needs of various industries. Discover more about how the MVW Inline can revolutionize your RFID label production by visiting our website and taking the first step towards future-proofing your manufacturing capabilities.