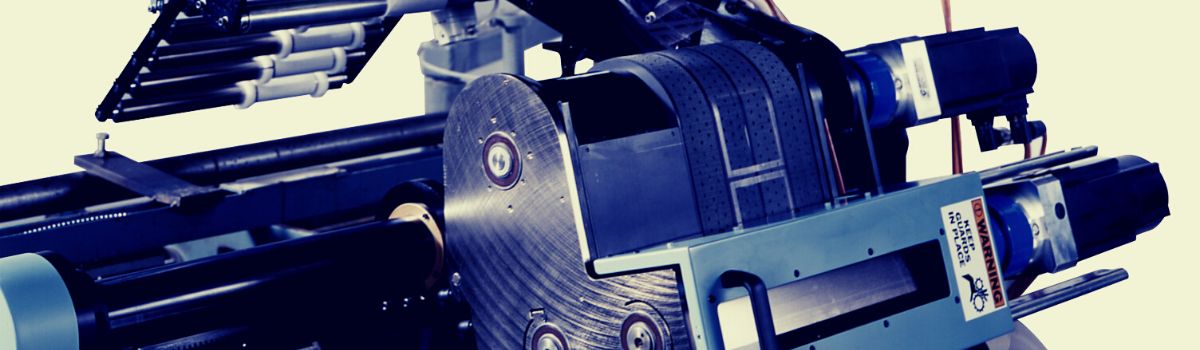

The continual introduction of unique and new materials in paper, plastics, laminates, film, foil, tapes, and nonwoven materials challenges web processors daily. The conditions of these materials, in addition to mechanical conditions, as well as surface and air conditions, often present big problems for web finishers associated with slitting and winding.

Slitting Technique, Knife Sharpness and Dust Level

Following some general rules for basic slitting techniques regarding the different types of slitting, equipment used, roller alignment, and winding techniques all impact slitting quality and efficiency.

Basic Slitting and Windowing Techniques

There are basically three different types of slitting techniques, with the thickness and type of material determining which technique should be used. The three basic slitting techniques include:

-

- Razor Blade Slitting

- Shear Slitting

- Score Cut Slitting

Razor blade slitting is appropriate for soft films such as polypropylene, polyethylene, vinyl, and light gauges of polyester, which are easily cut by razor blades. Shear slitting should be used for heavier gauges of polyester as well as most laminates and paper foil. Score cut slitting is beneficial when the material is too abrasive for razor blade or shear slitting or when quick changeover and set up is more important than the slit edge quality.

Knife Sharpness and Quality

The knives used are critical pieces of equipment for slitting processes and must be maintained properly for sharpness and quality. These knives are extremely sharp and should be handled with care whenever storing, sharpening, or maintaining the knives.

Some tips to handle knives correctly include proper handling and storage, such as storing on a mounted pegboard in a storage cabinet. Knives should be sharpened with a quick set ready to use. Wherever knives are handled, having a rubber floor mat will help to protect the knives if they are dropped accidentally on the floor. Having a wooden floor in this area is another common practice, and using wooden workbenches instead of aluminum or steel can also protect the blades. Never store knives in cardboard boxes as considerable damage can occur to the knives and the packaging.

Evaluate Knife Sharpness

A rough surface finish on a Shear knife can create a considerable amount of dust and cause damage when cutting. Polished and super-finished top shear knives with a surface finish of an RMS of 1 to 2 provide a much cleaner cut than knives with an RMS of 8 to 12. RMS stands for the Root Mean Square roughness and is a method of measuring peaks and valleys in a surface with lower numbers indicating a smoother finish. Rougher surface finished knives increase the likelihood of potential damage. Some old-school operators test the sharpness of their knives with their fingernail, but this is not recommended. Wearing safety gloves and dragging a cotton ball along the surface is a nonscientific way to check for snacks or burrs on the cutting edge.

Maintain and Minimize Dust Levels

Dust is often generated in slitting operations as the blades cut through various fibrous and nonwoven materials. Web finishers should employ a dust measuring system for periodic preventive maintenance to prevent an accumulation of dust. Some processors collect dust from specific areas on the machine and then weigh it on a gram scale; when it reaches a certain level, maintenance or knife changes are required.

Improving your slitting process entails matching the right type of slitting technique to your materials, maintaining knife sharpness, and minimizing dust levels, as well as having the proper roller alignment and winding technique in place. Speaking with an experienced web finishing and converter equipment manufacturer can help you to ensure that you are utilizing the right type of equipment properly to obtain the best results.

Tamarack® Products is a leading global supplier of converting equipment with more than 50 years of experience. We offer custom design, engineering, and manufacturing of specialty equipment for web patching, integrated label production, and continuous web applications. Contact us to learn more about improving your slitting process for your web finishing application.