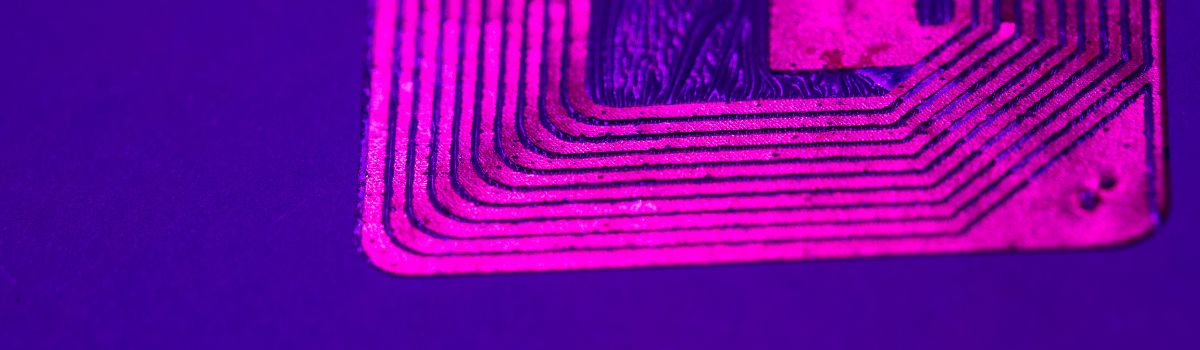

Many retailers today are telling their suppliers that they must have RFID tags on their products if they want to stock them in their stores. There are cost-efficient solutions for adding RFID tags, cards, or labels on products and many benefits in addition to meeting compliance requirements for customers.

Increasing Demand for RFID Tags

RFID tags provide many benefits such as real-time tracking which adds tremendous value for logistics in many areas of the supply chain. Many large retailers are now demanding suppliers include RFID technology for their products in order to do business. Walmart, for example, now requires suppliers to put RFID tags for all off-line and hardline categories with many other retailers like Nordstrom following suit. This is in addition to source tagging which was implemented in many electronics and apparel retailers many years ago.

This is not something to be put off for tomorrow, as the requirement is happening now. Walmart is requiring RFID tags for products sold in all US and Puerto Rico stores with a deadline of June 3, 2022, to have RFID tags and inlays tested and certified by the recommended RFID lab. A deadline of September 2, 2022, is set for all softline and hardline products such as toys, electronics, sporting goods, automotive products, and more to have RFID tags that are 100% readable or risk non-compliance.

Use RFID Technology to Your Benefit

RFID tags and labels improve logistics for your customers like stocking are selling products at Walmart, but can also provide many benefits to the manufacturer that can help to offset the cost of incorporating RFID technology. Incorporating RFID tagging at the source is a valuable investment that can provide greater cost savings to manufacturers. Utilizing RFID track and trace solutions enables companies to improve efficiencies and inventory management, fulfillment workflows, and dock-to-stock lead time.

Improving the accuracy of inventory and logistics also improves accounting and time spent on creating reports and/or billing. The real-time data that RFID technology provides also eliminates the risk of data entry error, improving accuracy and financial reporting for many companies and brands. RFID technology improves a company’s visibility from raw material, through work in process, to finished goods, shipments out the door, and beyond.

If you are forced to incorporate RFID technology, be sure to use it to your own advantage as well. Speak with an RFID inlay insertion specialist like Tamarack® Products to learn the most efficient and cost-effective solution for you.

Tamarack® RFID Inlay Insertion Solutions

Tamarack® Products offers RFID inlay insertion solutions to produce RFID tags, labels, and tickets in a single pass on your existing or new Flexo press. The MVW Inline RFID Inlay Insertion System simplifies integration with your price was servo-driven technology and operator-friendly controls. The MVW Inline RFID allows for quick setup and is usually installed after the press print stations, prior to finishing processes.

Tamarack’s MVW Offline RFID Inlay Insertion System produces RFID tags, tickets, and labels with an off-line platform that is configured to year specifications. The MVW RFID Inlay Insertion System includes reregistration to ensure that RFID inlays are placed in registered to your print specification, and can be configured with dry inlays, wet inlays, or both. The MVW can be designed for multiple lanes to meet high-volume production requirements, with multiple die-cut units in the finishing section.

Tamarack® Products offers more than 50 years of experience as an industry leader in providing innovative equipment for web finishing and RFID technology. We differ from other RFID equipment suppliers with our attentiveness to customer needs and ability to provide customized, modular, and scalable equipment. Contact us to learn more about incorporating efficient and cost-effective RFID inlay insertion technology into your process.