A variety of industries rely on Radio Frequency Identification (RFID) technology as an efficient and accurate tracking system for their products, employees, and inventory. RFID tags allow businesses to easily track each point of an asset’s lifecycle for better inventory management and monitoring.

RFID Technology

RFID operates by using radiofrequency waves and wireless communication to collect, store, and transfer data. RFID tags are read by a reader device using antennas and without needing direct line-of-sight with the object. This technology is mainly used for accurate tracking of objects, shipments, animals, or people.

Using RFID tag technology, wireless tags are developed that store the data information of a parcel or item and can be placed inside crates, boxes, or on individual items.

RFID System

The RFID tag system consists of several components that work together to deliver accurate and efficient tracking of items.

RFID Tag – Each RFID tag has a microchip within it that stores all the asset’s data. Passive and active RFID tags are the two primary varieties. Active tags can send data over a great distance since they have an internal power source. The RFID reader supplies electricity to passive RFID tags, which have a lower transmission range.

RFID Reader Device – The RFID reader, which can be stationary or mobile, analyzes the data from the tag. Readers placed at store entrances to stop customers from leaving with items they have not paid for is common practice for RFID technology and is widely used in theft protection strategies. RFID mobile readers can also come as handheld scanners and can wirelessly transmit information without the need for line-of-sight scans.

The two types of RFID readers are high-frequency readers, which are ideally suited for close-range applications, and low-frequency readers, which have a larger range. While low-frequency readers will work better for moving objects, high-frequency RFID scanners may be appropriate for immobile assets.

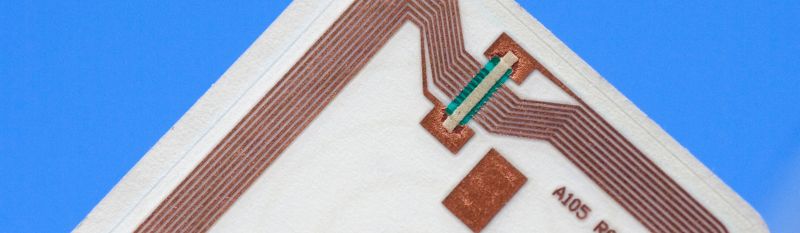

RFID Antennas – The RFID reader, which transmits radio waves and receives data from the RFID tag, includes an RFID antenna. An essential part of the complete RFID system, the antenna serves as the main connection between the reader and the tag and regulates the reader’s speed and range. Circular and linear RFID antennas are the two most common varieties. With each offering certain benefits and drawbacks, circular antennas produce a circularly polarized signal, while linear antennas produce a signal that is linearly polarized. The kind of RFID antenna used should be determined by the application. In general, linear antennas perform better for longer-range applications while circular antennas are better for short-range ones.

Manufacturing RFID Tags

Before the tags are created, the aluminum antenna is made from bobbins of aluminum. Once the antenna takes shape, the RFID chip which stores the information that is transmitted using the antenna, is inserted in the antenna using a bonding machine.

A converting machine either uses a dry inlay or a wet inlay that becomes covered by an adhesive substance on siliconized paper. The type of tag needed dictates how the material is measured and cut. The excess material is removed so just the wet inlay is left in the shape of a tag over the siliconized paper, which can then be removed and placed on any surface such as a tag.

RFID Tag System Applications

RFID tag systems bring immeasurable value and efficiency to asset-tracking processes and can be used in a variety of applications such as:

-

-

- Hospital bracelets to monitor patients

- Construction equipment and tools

- Landscaping materials

- Manufacturing

- Retail industry for theft prevention and inventory control

- Electrical and plumbing industry

-

RFID tags can essentially be used in any industry that is looking to manage its inventory, track its assets, reduce the risk of human error, and increase productivity in order fulfillment more efficiently.

Tamarack® Products has over 50 years of experience in the web finishing industry and offers fully customizable equipment solutions such as the MVW Inline RFID inlay insertion system. The MVW Inlineis scalable, modular, and servo-driven with operator-friendly controls.

Tamarack® Products delivers RFID technology solutions with our fully scalable and customizable MVW Inline RFID inlay insertion system that can be fully integrated into your current flexo press. Contact us for more information about the MVW Inline RFID inlay insertion system and our additional integrated web finishing solutions.